When it comes to ensuring adhesion, you don’t just need a measurement tool

When it comes to ensuring adhesion, you don’t just need a measurement tool

You need a collaboration tool.

Use data—not guesswork—to make better decisions.

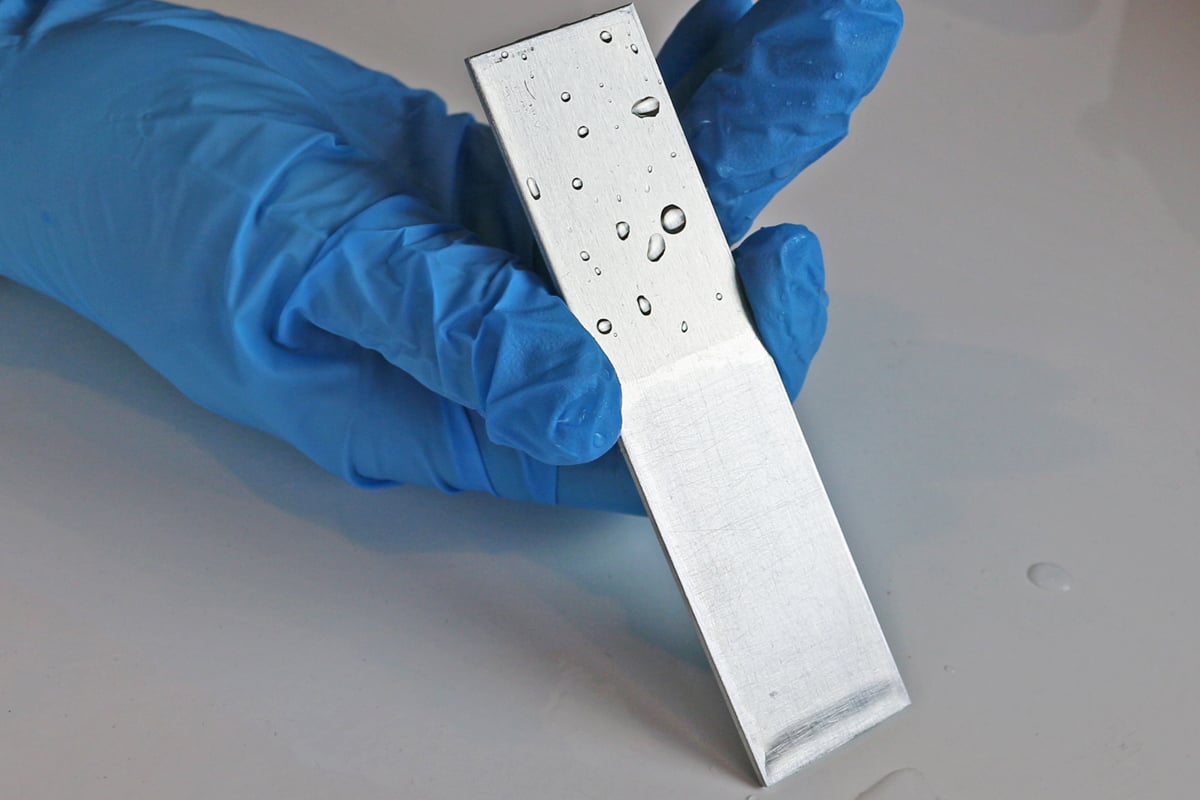

Introducing surface intelligence. Sneaky adhesion issues can plague production and hamper innovation at every step of the manufacturing process, from product development to production. Our surface intelligence technology can accomplish what traditional QA cannot—giving you real-time data right from the lab and the production line that can be easily shared across the enterprise.

Put decision-making data in the hands of those who need it most.

Solve.

Prevent.

Control.

Meet our makers.

.png?width=177&height=254&name=sherwin-williams-consumer-goods-transparent-logo%20(177x254).png)

.png?width=177&height=131&name=lockhead-martin-aerospace-transparent-logo%20(177x131).png)

.png?width=160&height=70&name=procter-and-gamble-p%26g-consumer-goods-transparent-logo%20(160x70).png)

.png?width=177&height=67&name=fiat-chrysler-automobiles-fca-automotive-transparent-logo%20(177x67).png)

.png?width=177&height=147&name=medical-stryker-transparent-logo%20(177x147).png)

Networked Solutions

BConnect

The first and only surface intelligence platform enabling you to effortlessly assess surface readiness for bonding, coating or sealing at any point in the production process—and share information seamlessly across processes and functions, even continents.

Trusted partnerships in some of the most demanding and high-stakes industries.

Sharing surface intelligence data and insights helps teams collaborate.

Brighton Science is

the global leader

in surface intelligence.

Tell us your goals or challenges, and we can advise you on specific solutions you can put to work immediately or build into your optimization processes.

What could this mean for you?