Certainty is the goal of every manufacturing process. Manufacturers need to have total confidence that every aspect of their production process will go according to plan. The adhesion process needs to be controlled just like any other production operation, with accuracy and ongoing monitoring. Manufacturers need to know that when they apply an adhesive, coating, paint, ink, or any other surface treatment--it will stick every single time.

How Can You Control the Certainty of Adhesion Processes?

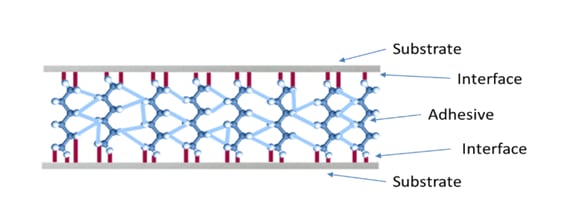

Current industry benchmarks for adequately prepared material surfaces warrant critical reevaluation by manufacturing and quality managers. The new benchmark needs to be founded on a scientific understanding of what is occurring on the surface. Shifting the perspective to a science-based foundation is crucial, demanding a deeper understanding of the phenomena occurring at the surface level. Notably, all surface preparation processes exert their influence on the uppermost three to five molecular layers of the material, highlighting the need for precise control and targeted optimization.

By removing material (e.g., abrading, media blasting, particulate washing) and by modifying the chemical nature of the surface (e.g., plasma treatment, solvent cleaning, chemical etching), the uppermost molecular layers are being altered or displaced. This is a crucial principle to understand in order to control adhesion outcomes fully, and it is usually the least understood element in manufacturing.

There are three underlying elements that need to be controlled for successful adhesion:

1. Composition of the adhesive or coating material

2. The adhesive or coating application and curing processes

3. The composition and properties of the first few molecular layers of the surface receiving the adhesive or coating: 'Surface Preparation'

Typically, it is the surface preparation element that gets short shrift when manufacturers are planning adhesion processes or trying to solve existing adhesion failures. Without focusing on how control of this key element affects adhesion, it can feel like a never-ending cycle of trial and error. Since adhesion is a function of chemical reactions occurring on the surfaces of two components bonding to each other, it needs to be approached as more than a mechanical operation.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Consistently Achieve the Change You Require

When manufacturers can rely on the consistency of their surface preparation process to achieve the chemically favorable surface they require to ensure adhesion, then they can begin to build that certainty they hope for. The clearest and surest path to certainty is to quantify each of those aspects of the production process where uncertainty lurks.

There is an inevitable variation in production processes and environments, but if the focus of control is on the material surface, then the impact of these variations can be understood and compensated for. Implementing a quantitative measurement of surface quality at every point where there is uncertainty about the state of the top molecular layers of a material is the quickest way to seize control of the entire process.

If an adhesion process has a set, quantifiable specification for precisely what a fully-prepared surface needs to be before the adhesion step, then manufacturers are freed up to concentrate efforts on achieving this value every time. This simplifies the equation. If you know you have a surface that measures at value [A], and you require that surface to measure at value [B] to ensure proper adhesion, then you can weed out any steps and processes that do not result in value [B].

How to Quantify the Uncertainty

In order to place a quantifiable value at each point where the surface can be changed (we call these Critical Control Points), a surface inspection method with a numerical result is required. Equipment that will incorporate into a production process and provide this value is required to seamlessly take the necessary measurements and gain insight into how to adjust parameters and practices to get to the desired goal. This will ensure consistency. If the specification is not met, then the material does not proceed, and adhesion failure is fixed before it starts.

Partnering with surface science experts is necessary to fully understand how to properly optimize the parameters and practices that might need to be adjusted in order to achieve reliable adhesion. Manufacturers can find help to make these changes thoughtfully and based on data rather than hope and speculation.

The risks associated with adhesion failure can be really high. It is critical that manufacturers re-evaluate their manufacturing processes through the lens of what changes are occurring to the top molecular layers of a surface.

Optimize the power of next-gen connectivity with data & surface intelligence.

Failure and rework impact production rates, increase costs, and can delay the launch of a new product. These challenges quickly gobble up personnel's time and prevent them from having the time to focus on innovating, developing new products, or optimizing. Warranty claims and recalls can be costly ways to realize there is an adhesion problem. Solving these issues upfront can save companies a fortune in the long run.

To find out more about developing a surface quality specification that fits your operation, download the eBook "Manufacturer's Roadmap to Eliminating Adhesion Issues in Production."