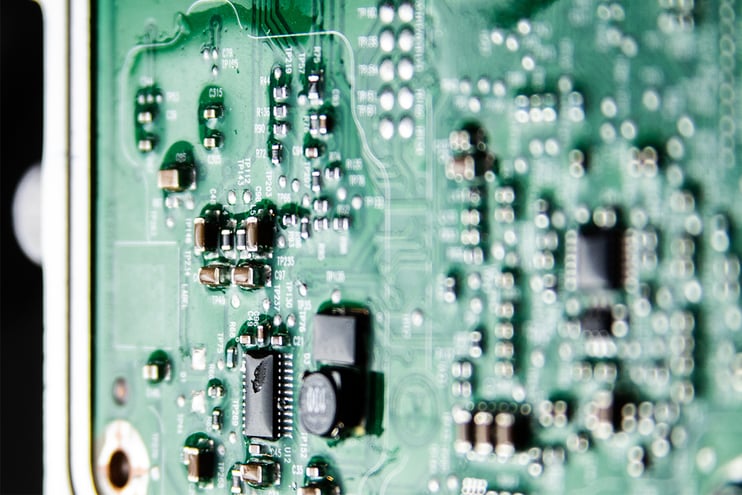

The widespread use of electronics in all manufacturing sectors has presented distinct difficulties. Manufacturers are responsible for safeguarding these electronic devices in harsh conditions that render electronics susceptible to even the slightest traces of moisture, particles, and environmental contaminates.

This article will go through the top four common barriers to the successful adhesion of conformal coatings.

What are Conformal Coatings?

The issue of safeguarding electronics components from environmental conditions can be confronted through conformal coating. Conformal coating is a thin coating material (usually 25-75µm thick) of polymeric film (Parylene and acrylic are popularly used, depending on the application) that covers and ‘conforms’ to the circuitry and connectors of printed circuit boards (PCB) to act as a barrier against contamination, durability against extreme temperatures, defense against moisture and corrosion.

The coating process of a conformal coating is also critical to performance success. Common conformal coating application methods include:

-

Manual spray application: often used for low-volume production

-

Automated spray gun: ideal for high-volume assembly

-

Selective coating: used to apply the coating to select areas on the PCB and is suitable for high-volume production

-

Dipping: used for applying the coating on both sides of the PCB

-

Brushing: often used for repair and rework and can be time-consuming

Common types of conformal coatings include:

-

Acrylic conformal coating

-

Epoxy coating

-

Silicone conformal coating

-

Urethane (polyurethane) conformal coating

-

Water-based conformal coating

-

UV curing conformal coating

While the capability of conformal coatings enhances the protection and reliability of electronics, manufacturers have often overlooked a pivotal element to dependability in this system: surface condition.

4 Common Factors that Could Lead to Coating Failure

1. No Clean Flux Residues

The name of these widespread flux residues is a bit of a misnomer in that it gives the impression that once this is applied, there is “no cleaning” necessary before conformal coating. All flux residues, including no-clean flux residues, need to be properly cleaned and thoroughly removed so they don’t interfere with the coating placed over them.

Before proceeding, understanding the chemical compatibility between the residue and the conformal coating is essential. Often, no-clean flux residues provide a false sense of safety that can lead to over-application, causing de-wetting (when the conformal coating pulls back from the residue). Ultimately, if no clean flux residues are not properly removed, they become a contaminate and can result in poor durability, including cracking and sometimes corrosion if moisture is allowed in.

2. Solder Mask

Another common and necessary part of electronic component construction is the solder mask. This is the typical green, lacquer-like coating that covers the copper layer of a PCB in between the solder pads where components are attached. This covering protects the copper traces that connect the components that populate the board from coming into contact with other metals and conductive materials. This mask helps prevent solder bridges, solder jumpers, and other issues that may lead to shorting and unreliability. However, If the solder mask's surface condition is not considered, then the conformal coating overtop may not be able to secure a consistent and reliable bond. This is usually the layer that has direct contact with the conformal coating and, therefore, is crucial to the adhesion process.

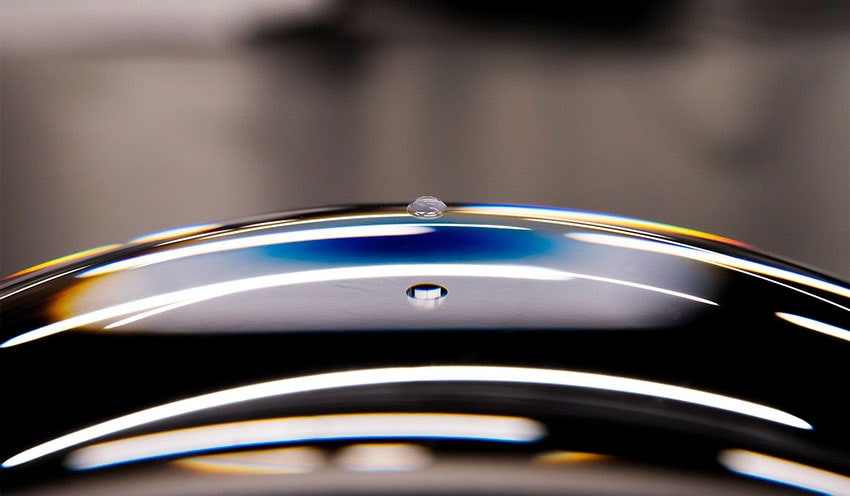

3. Low Surface Energy & Adhesion

PCB and the pre-conformal layer coatings commonly have a significant polymer presence, which is an intrinsically low-energy material. Surface energy directly relates to the level of attraction a surface has to other materials and adhesion performance. A high-energy surface is usually very amenable to bonding, and a low-energy surface is not. The low-energy surface requires treatment or cleaning to reach a surface energy optimal for adhesion.

To read about the fundamentals of adhesion and why the top 3-molecular levels of a surface matter to adhesion, read this article.

In the case of the PCB, if it is not properly treated for adhesion (common polymer treatments include plasma, corona, or flame treatment), conformal coating adhesion will not perform as expected. Adhesion failure of conformal coating can lead to delamination, chipping, blistering, and other failures that leave the electronics vulnerable to harsh environments.

4. Improper Surface Treatment & Cleaning

Treatments and coatings before applying the conformal coating can often be administered improperly due to a lack of understanding of surface chemistry. Atmospheric plasma treatment, a widely used method for preparing electronics for adhesion, bombards the substrate’s surface with excited molecules, free electrons, and ions that change the chemical makeup of the surface, raising its surface energy. Often, there is over-treatment of plasma or flame treatments, over-application of a coating, or just insufficient cleaning of the surface before the coating.

Cleaning techniques range from wiping with isopropyl alcohol to cleaning with compressed air to remove particulates and debris. Insufficient cleaning is often due to not considering the chemical surface state and, therefore, not being able to clean or activate the surface to a degree optimal for adhesion. Improper surface treatment results in poor adhesion, leading to adhesion failures such as fish eyes, dimpling, moisture corrosion, and damage due to debris that a strong and complete conformal coating can resist.

Another factor that is often overlooked is the effectiveness of treatment over time. If the immediate result of a coating passes all currently utilized tests, then typically, the inspection stops. However, it's prevalent for that bond to become unstable over time while in storage or even within 48 hours of the application of the coating. If treatment is not done with this in mind, the problem will never be solved.

To ensure that none of these factors slip under your radar, you need a way to monitor and measure the surface state and the effect of each protective layer. You need to know when, where, and how to evaluate a surface's readiness for adhesion. It comes down to rethinking the entire approach to adhesion.

To learn more about managing your adhesion process and ensuring your coatings are free from failure, download the eBook "How to Increase Electronics Manufacturing Quality Through Cleanliness."