Brighton Science's Founder and Chief Scientist, Dr. Giles Dillingham, and Research and Development Chemist, Brooke Campbell recently collaborated with NASA scientists and researchers from the Department of Electrical and Computer Engineering at the University of Virginia on an article published in the Journal of the Society for Applied Spectroscopy.

The article covers research into the sensitivity of laser-induced breakdown spectroscopy (LIBS) and how it compares to x-ray photoelectron spectroscopy (XPS) to detect and measure surface silicone contamination.

Click here to download the full article.

Correlation of Trace Silicone Contamination Analyses on Epoxy Composites Using X-ray Photoelectron Spectroscopy (XPS) and Laser-Induced Breakdown Spectroscopy (LIBS)

By Rodolfo Ledesma, Frank Palmieri, Brooke Campbell, William Yost, James Fitz-Gerald, Giles Dillingham, and John Connell

Abstract

Surface treatment and surface characterization techniques are critical to ensure that adherents are chemically activated and free of contaminants before adhesive bonding. Silicone contamination from mold release agents and other sources can interfere with interfacial bonding, decreasing the durability and performance of bonded composite structures.

It is necessary to have tools and methods that can be used in a production environment to reliably detect low levels of contaminants in a rapid, simple, and cost-effective manner to improve bond reliability.

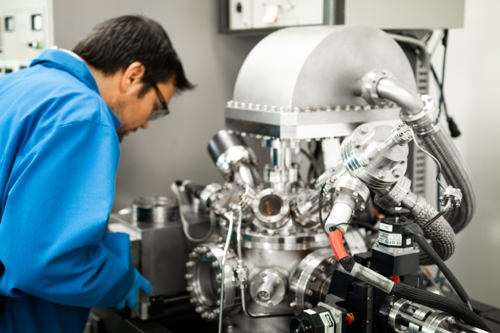

In this work, surface characterization of carbon fiber reinforced polymer (CFRP) composites with epoxy matrix was performed using laser-induced breakdown spectroscopy (LIBS), and the results was compared with those obtained from X-ray photoelectron spectroscopy (XPS). Laser-induced breakdown spectroscopy offers many advantages over XPS in terms of ease of use, sample preparation, and real-time results.

The objective of the comparison was to study the sensitivity of LIBS and to investigate the quantification of the surface species measured by LIBS. Another objective was to assess the reliability of each technique for surface contaminant characterization. The as-processed CFRP panels had trace surface silicone contamination from the fabrication process, the source of which was not investigated. The composites were laser treated at select average laser power levels, resulting in varying levels of contamination reduction. The Si atomic percentage measurements using XPS were conducted on both control and laser-ablated surfaces.

The results showed an excellent correlation in Si concentration between the two techniques.

Click here to download the full article.