When adhesion failure plagues a manufacturing process, it can be particularly disruptive. A production process may be humming along just fine, and then it suddenly becomes clear that a coating is uneven, or paint is chipping (when it wasn’t before), joints are weaker than they had been, or film is delaminating. These instances of adhesion not working properly can be minor if caught and fixed early enough, or they can be catastrophic to the performance of the end product.

Industries demanding high reliability require adhesion to work completely every single time, with no exceptions. The risks of medical devices not functioning properly, faulty wiring in navigational equipment caused by poor coating, or the seal used on a car engine part failing are all too great to leave to chance.

Manufacturers need to suss out the source.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Finding the Root Cause

In order to do this, there have to be some preliminary steps taken. First, a well-defined understanding of what adhesion success and failure actually need to be established. This seems obvious, but putting skin on the bones of the issue and formalizing the performance requirements helps create achievable and manageable standards. This clear, diagnostic approach also gets to the heart of what the trouble truly is. It could be an inadequate adhesive, a faulty curing process, or an issue with the state of the material surface. Systematically checking off these possibilities gets you that much closer to the source of the problem.

It can be a knee-jerk reaction to only say: if the adhesion failed, it must be the adhesive. This is a fine place to start. It is logical to contact your adhesive vendor and look into handling requirements and curing methods if you are experiencing an adhesive failure. But if this is where the investigation into the root cause ends, the full picture will never be seen.

If the adhesive and the curing process are looked into, and the adhesion issue persists, in our experience, this means the material surface holds the key to understanding where the problem is originating.

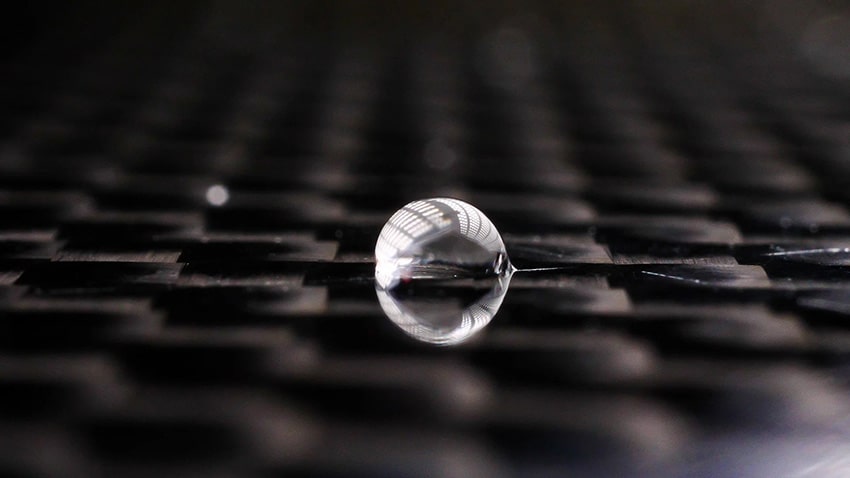

The surface does not give up its secrets readily

Some fundamental principles about adhesion have to be understood in order to fully grasp what the surface tells you upon inspection. Adhesion is a chemical reaction between the top few molecular layers of the material surface and what is being applied to it. It is impossible to merely do a visual test and determine if the surface is ready for adhesion.

Look Deeper

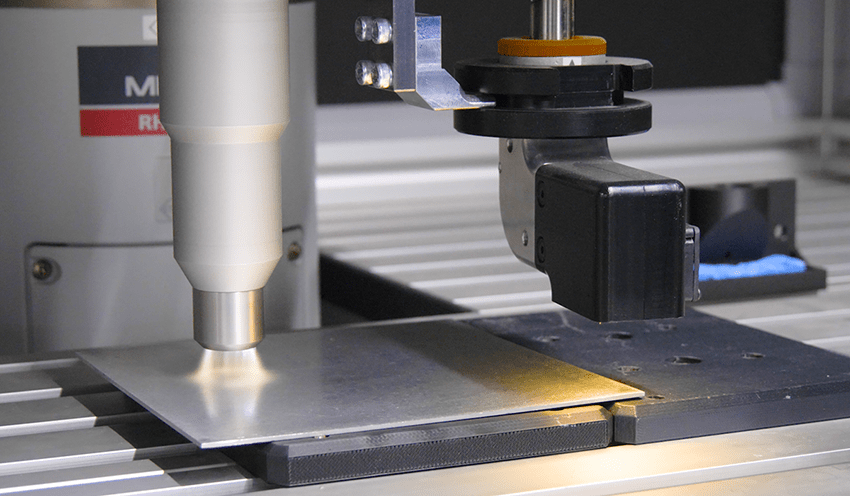

The surface needs to be adequately prepared before adhesion can be successful. This includes cleaning and treating the surface, but it also means that these processes need to be controlled and optimized. If a surface is cleaned or treated but not to the extent that ensures a successful bond, then failure is inevitable. Not validating these steps is potentially the cause of the problem and is definitely a source of inefficiency in the process.

The only way to truly optimize the cleaning and treatment steps is to have a baseline quality value determined beforehand. If a surface has an undetected molecular contaminant or is in an unknown state, then it will be impossible to know to what extent it needs to be cleaned or treated. This same principle needs to be applied throughout the production process so that any time a surface is intentionally or unintentionally altered, it can be quantified and controlled.

Revolutionize Your Manufacturing with Surface Quality Inspection Technology.

Contamination and Chemical Changes Can Occur at Many Different Points Along the Way

Each point needs:

- Identification - figure out every point a material surface is or can be altered in any way throughout the entire production process, as well as in storage

- Quantification - the state of the material surface needs to have a quantifiable value attached to it at each point

- Verification - appropriate actions need to be taken to ensure adhesion success if the numerical spec is not met at each point.

We call each of these inspection areas Critical Control Points (CCPs). Keeping control of these CCPs means that the source of adhesion failure will be revealed or blocked before it happens. Adhesion failure causes can’t hide when you are controlling your entire process.

Being able to fully troubleshoot all of these possible sources of the problem is not actually that easy. If it were easy, then manufacturers would have solved these issues a long time ago. But you’re not alone. It is common to not control these CCPs because, until now, the material surface has not been emphasized in adhesion maintenance. Most manufacturers have never been trained about where to look and lack the equipment with the necessary sensitivity to really measure the surface quality state.

Discover the Critical Control Points in your manufacturing process today. A free Production Line Process Walk is available to start gaining insight into where adhesion failure is originating. You don’t need to tackle the problem alone.

To learn more about eliminating adhesion issues, please download the free eBook titled "Manufacturer's Roadmap to Eliminating Adhesion Issues in Production."