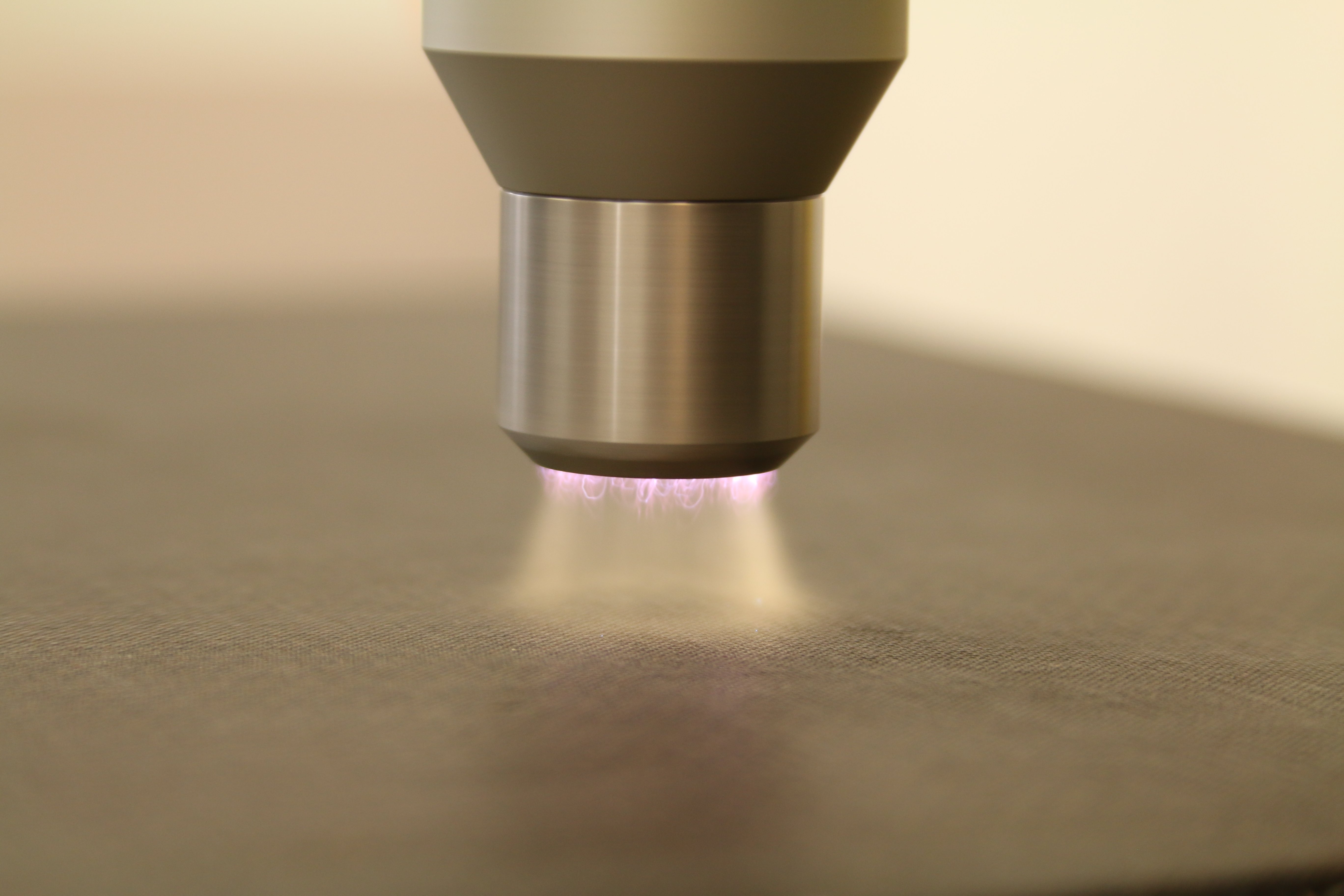

Flame treatment is a surface activation treatment process used to chemically modify a surface for better adhesion. This process is typically used on low-energy surfaces that can be difficult to adhere to, such as plastics and composites. The treatment is also very gentle, posing low risk to the material. Flame treatment uses a carefully controlled blend of natural gas and air to create a hot, oxygen-rich plasma. First, the heat removes contaminants. Then, after contaminant removal, the oxygen-rich plasma activates the surface by partial oxidation. The result is a clean, high-energy surface that is in an excellent state for printing, painting, coating, or bonding.

Flame treatment is used in a wide array of industries, including film and flexible packaging, consumer goods, automotive, textile, medical device, and even aerospace. Flame treatment may be used on a web or a smaller, specific part. It is especially useful for its uniform treatment and ability to treat diverse materials from cardboard to composites.

A major application for flame treatment is in the treatment of TPO (thermoplastic olefin) automotive parts such as bumper fascia and interior components. Another large application is in the treatment of appliance components and golf balls prior to coating and printing. It is also used extensively on film prior to printing and laminating.

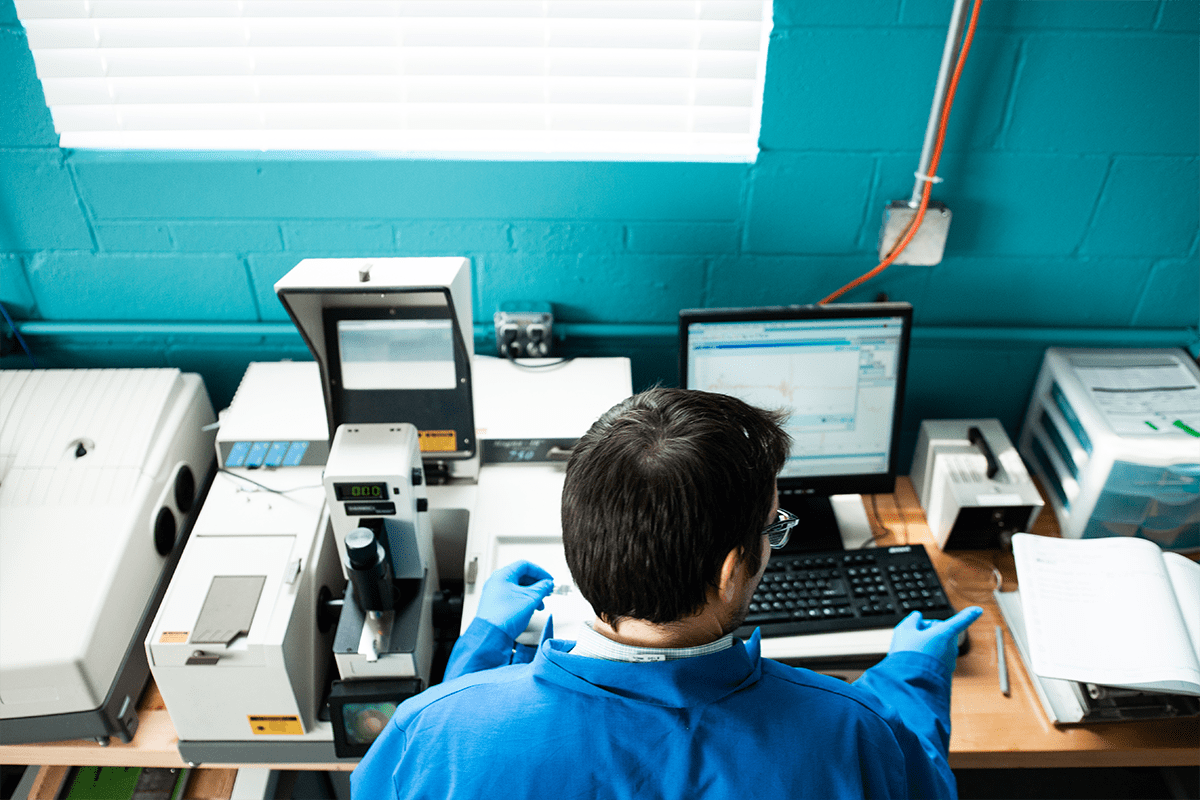

Brighton Science's Surface Analyst™ is used by many manufacturers to monitor and verify flame treatment performance. By measuring the surface energy of a material pre- and post-flame treatment, the Surface Analyst will help manufacturers determine the appropriate flame treatment level necessary for optimal performance. Once the baseline specification is defined, manufacturers can then monitor the determined level throughout the entire production process.

Get hands-on with your surface cleanliness with the Surface Analyst 5001.

Finding the “sweet spot” in flame treatment is important, as undertreatment can leave contaminants on the surface, and overtreatment can begin to harm the material. Brighton Science has in-house manual flame treatment capabilities to provide customers with process development work to find the right parameters for their flame treatment.

Read how you can implement surface quality measurements and gain surface intelligence that will enable breakthrough performance and optimization by downloading the eBook "Manufacturer's Roadmap to Eliminating Adhesion Issues in Manufacturing."