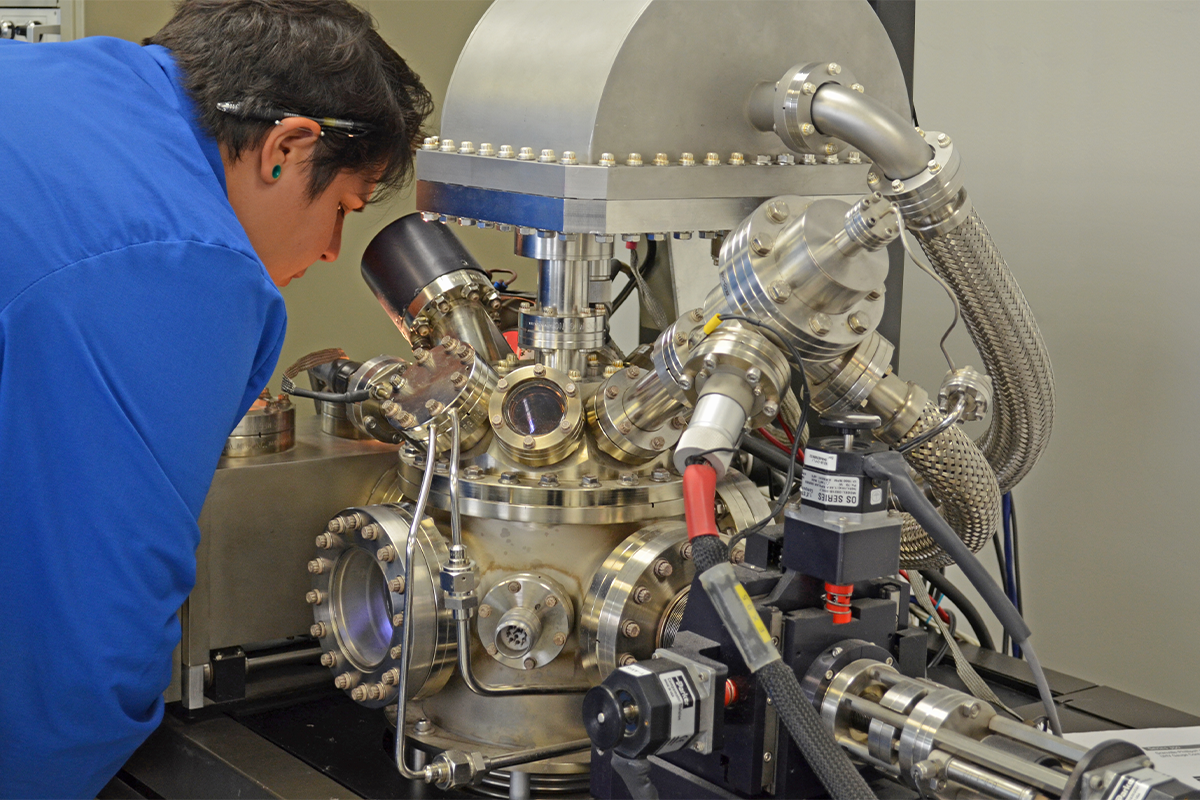

In the Brighton Science Materials and Processing Laboratory, magic happens. Or, at least, it seems that way. In the lab, our specialists see the unseen. They use expertise, specialized tools, and data to reveal the invisible.We’re talking about invisible surface chemistry, of course.

“Usually, the customer knows there’s something wrong with the surface, but they don’t know what,” says M&P Engineer and R&D Chemist Brooke Campbell. She and Elizabeth Kidd, our R&D Chemist and custom application scientist, combine their analytical expertise with the instruments in our highly sophisticated lab; they evaluate, characterize, and optimize critical surface processes for industries from consumer goods, medical devices, aerospace, and everything in between.

Using highly advanced instruments such as the XPS (X-ray Photoelectron Spectroscopy), FTIR (Fourier Transform Infrared Spectroscopy), Instron, goniometer, and of course, the Surface Analyst, the lab performed various tests to evaluate the surface. They then characterize the issue. This usually entails identifying contamination or an issue with surface preparation. Lastly, they deduce an answer.

Get hands-on with your surface cleanliness with the Surface Analyst 5001.

In some instances, Brooke explains, the customer has implemented an instrument in their manufacturing processes. All is well until they come across a batch that is out of spec. They know there isn’t a problem with the instrument, but that’s it. So, their puzzle makes its way to the M&P lab for investigation. Specialists in Brighton Science's laboratory investigate and identify the step in the process that needs to be altered and suggest a way in which to make that alteration in order to ensure specifications are met.

“Another thing we show is feasibility. Can we do this? The customer wants to see the Surface Analyst on their own product. We do that to show it’s possible,” Brooke explains.

A specific issue involved a composite manufacturer experiencing bonding problems. They were using a subjective, destructive method. We bonded, cured, and broke the composite using the manufacturer’s written specifications. From there, we identified surface preparation issues and edited the process, and defined the necessary contact angle parameters to ensure the proper surface cleanliness was reached after every surface treatment. We showed them that the Surface Analyst could be used on their surface, and we gave them an analytical method to assess their surface with confidence.

Elizabeth reiterates, “We are verifying the Surface Analyst’s ability.”

Brooke concludes, “We use the lab’s analytical instruments and methods to show there’s a chemical component.” Some unseen contaminant. We then figure out how best to address that component. Is it magic? No. It’s something even more extraordinary; it’s science.

To learn more about how the M&P lab can help improve your critical surface processes, visit the services page and read about the Process Development Packages.