The water break test is a common way for manufacturers to test the surface cleanliness of metal surfaces. Compared to other legacy cleanliness tests, it is relatively simple to perform. However, the results rely almost entirely on the subjective eye of the person performing the test.

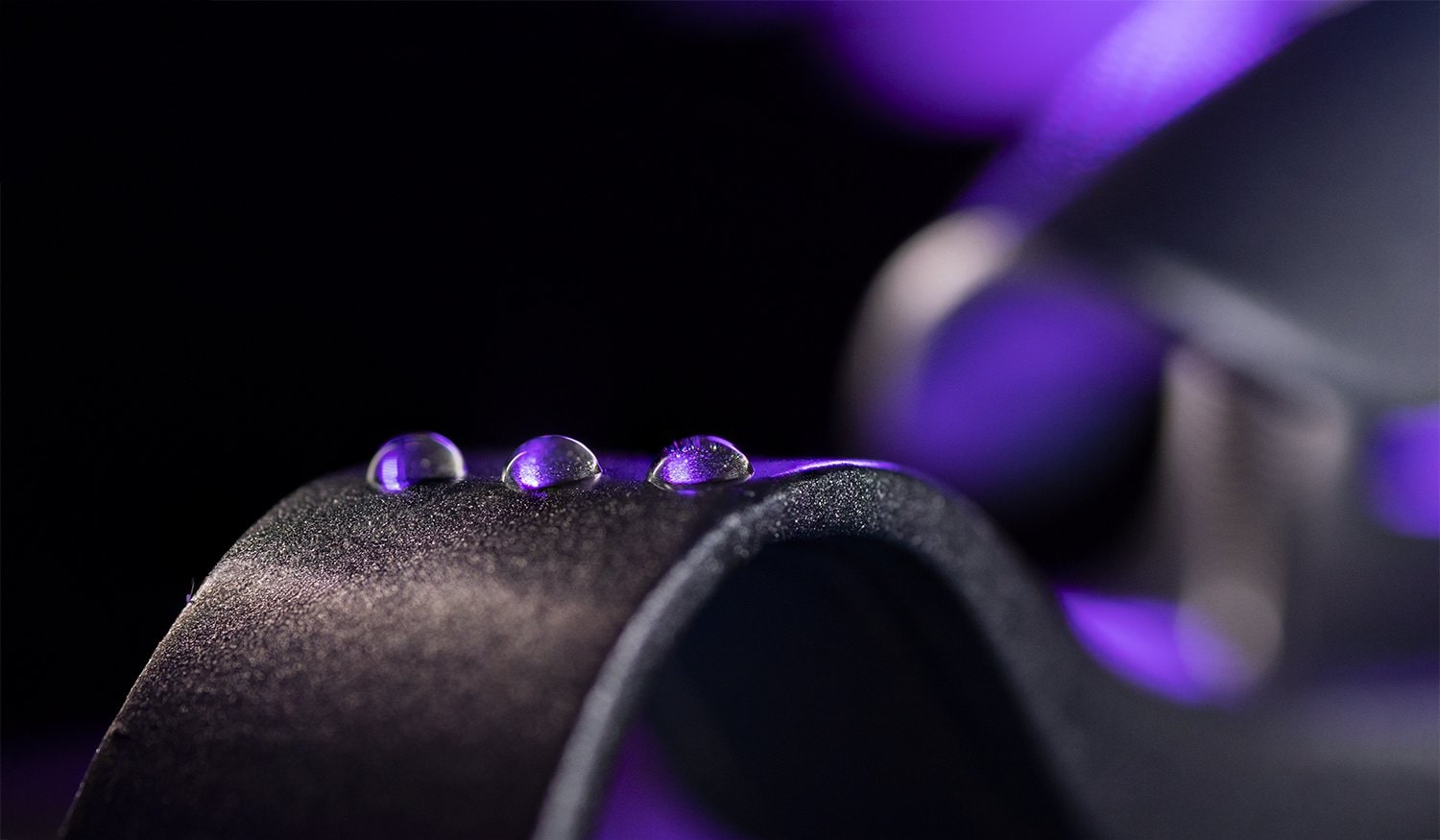

Hydrophobic contaminants and residues that repel water (causing water to bead up) can adversely affect adhesive bonding performance. The utilization of water break tests allows individuals to visually evaluate the presence of these contaminants. However, this testing method has critical limitations despite being non-destructive by relying solely on water. It is unable to detect surfactants or other hydrophilic substances on the surface. Moreover, if impure water is introduced during the test instead of purified water, it can lead to the presence of contaminants on the surface, potentially causing inaccurate test results.

What is the Water Break Test, and How is it Performed?

The ASTM-F22 Handbook sets the standard for water break tests. To perform a water break test, a material substrate is dipped into water and withdrawn vertically. In some instances, the water is sprayed or poured onto the surface. The water's behavior on the surface is visually assessed by the technician conducting the test. The analysis performed by the technician is based on their subjective observation. Water break tests are often used for parts washing and are generally unsuitable for precision-cleaning applications.

In order to ensure strong and dependable adhesion, it is necessary for surfaces to possess a high surface energy that attracts adhesives, paints, inks, or other coatings. A clean surface typically has high surface energy, and when conducting the water break test, it should result in the water sliding off the entire surface in an unbroken sheet. If the substrate or part is clean, the water will spread out evenly due to its attraction to the surface. If the water beads on the surface, this indicates there are contaminants on the material's surface. The behavior of water on a surface can provide valuable insights into its adhesion capabilities. However, relying on the subjective and difficult-to-control nature of the water break test makes it unsuitable for process control in modern manufacturing.

How Accurate is the Water Break Test?

Water break tests are used primarily for metal surfaces to identify surface contaminants on incoming raw materials or after surface processes, such as cleaning processes, etching, anodizing, painting, priming, coating, grit-blasting, or sanding, have occurred. These tests can be messy and frequently result in unintended contamination from using impure water.

The water break test is limited by the time it takes for the part to dry completely. Adequate time must be given for the part to dry after the test, which may involve manually wiping the substrate or using a baking process. However, both methods can introduce contaminants or change the surface chemistry of the part unintentionally—rendering the validation test ineffective.

A Critical Control Point (CCP) represents any specific opportunity throughout the manufacturing process when a material surface has the potential to change inadvertently. A non-destructive methodology that captures surface quality precisely at any point in the production process is required to validate process control over CCPs. The water break test does not hold up to these challenges because the testing methods themselves can be a source of contamination.

Although technicians can be trained regarding how to conduct a water break test, there are no definitive pass/fail standards for the water break test. This leaves test results vulnerable to inconsistent standards within a company, individual plants, and throughout suppliers. This highly subjective test does not support the rigorous accuracy needs of tightly controlled manufacturing industries.

Another drawback of the water break test is its limited sensitivity. Even if a surface looks clean visually, it may still be contaminated. Conducting multiple tests on the same material can lead to inconsistent outcomes. False positives are quite frequent with this test, meaning that it may mistakenly indicate a surface as clean when it is actually contaminated.

A New Alternative to Water Break Tests

Maintaining objectivity and capturing consistently accurate results can be achieved with the appropriate processes and equipment. The Surface Analyst™ technology uses contact angle measurements that are sensitive to the top 2-3 molecular layers of a surface where adhesion occurs. The Surface Analyst™ deposits a single drop of highly purified water on a surface to accurately predict adhesion success. This reliable and quantitative surface quality measurement is completely non-destructive and poses no threat to the surface or part being measured.

The Surface Analyst can measure the water contact angle on any surface or surface orientation regardless of shape, size, geometry, or roughness. Unlike a water break test requiring a part to be removed from production to test surface cleanliness or adhesion readiness, the Surface Analyst can perform measurements on actual parts during the manufacturing process.

Instant access to water contact angle measurement data allows for immediate action in the event of contamination detection. By automatically calculating the contact angle, the Surface Analyst eliminates any potential subjectivity from the operator. Unlike the binary go/no-go result that a water break test provides, the Surface Analyst produces quantitative data, allowing for an accurate understanding of a surface's characteristics. This enables manufacturers to confidently determine contamination levels and pinpoint specific contamination locations. As a result, timely and targeted remedial measures can be implemented.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Rethink Water Break Tests

Highly engineered materials are becoming the norm in complex manufacturing environments. Manufacturers now rely on a wide array of raw materials, including custom-designed metals, polymers, and an extensive variety of advanced composites. Advances in part molding technology have led to the development of parts with increasingly complex geometries. Water break tests are not practical in this increasingly sophisticated manufacturing environment. Although water break tests were historically effective for large, flat surfaces, this test is becoming obsolete as manufacturers embrace new technologies for highly sophisticated power production.

The Internet of Things (IoT) and leveraging the power of data through Industry 4.0 processes are transforming how manufacturers collect and analyze test results. Water break tests are not well suited for manufacturers seeking to gain actionable, traceable, and quantitative test results about surface quality. Data-driven process control requires sophisticated testing methodologies that seamlessly capture and share all relevant surface analytics data.

Using surface intelligence technology, your business can accomplish what traditional QA cannot—giving you real-time data right from the lab and the production line that can be easily shared across the enterprise.

To find out more about an alternative to the water break test, download the eBook "Manufacturers Roadmap to Eliminating Adhesion Issues in Production."