There are numerous obstacles to achieving and then maintaining a clean material surface. But there is one element that carries through the entire product lifecycle and can have a massive impact on the adhesion performance of the final product: TIME.

Time takes its toll on surface quality. Time can be a sinister interference in preserving a surface that is the most amenable to adhesion.

Whether you are developing a product that will be coated, printed, painted, bonded, or sealed, it is necessary to understand the risk of time and how it can impact the material surface before these processes. Typically, the adhesion or coating operation occurs after several steps have been employed—time factors into each and every one of these points along the way.

How can you fight against a relentless force like time? Well, just like every variable that can affect the success of an adhesion or coating process, the impact of time needs to be understood, measured, and controlled.

Here are four crucial questions to ask when trying to understand how time may interfere with any of the previously mentioned processes:

- What material are you manipulating?

- How are you manipulating it?

- What is the environment you are manipulating it in?

- How is it being handled, stored, and shipped?

Getting clear, well-defined answers to these questions puts the control in the hands of product development teams and manufacturers to prevent adhesion failure or eradicate it at the root cause.

Rethink your adhesion manufacturing processes with Surface Intelligence.

1. What Material are you Manipulating?

Aging does not manifest itself in all materials equally. When thinking about how time affects different types of materials, you can lump them into three distinct categories:

Crystalline materials

This group includes metals, glass, and ceramics with highly rigid molecular structures. These materials have high energy, which means they have very reactive surfaces. They age rapidly and are easily contaminated.

Thermosets

This includes carbon fiber-reinforced polymers, polyurethane, and other materials that are very moldable upon creation but become extremely rigid after curing (usually with heat.) These have lower surface energy than crystalline materials and require manipulation like fracturing through abrasion or activation through plasma treatment.

Thermoplastics

This name describes any rigid polymer that is cooled but elastic and soft when heated. This includes plastics like polyethylene, polypropylene, nylon, and others. These are prepared for adhesion processes, like printing on a plastic bottle or label by using corona, flame, or plasma treatment. One issue typically unique to thermoplastics is the tendency of molecules found in the bulk of the material to “bloom” to the surface over time and create a surface that is not chemically suitable for the desired adhesion.

2. How are you Manipulating the Material?

As stated above, what you do to prepare a surface for an adhesion or coating process greatly depends on the material. These various treatments, cleaning, and preparation steps also have different shelf lives.

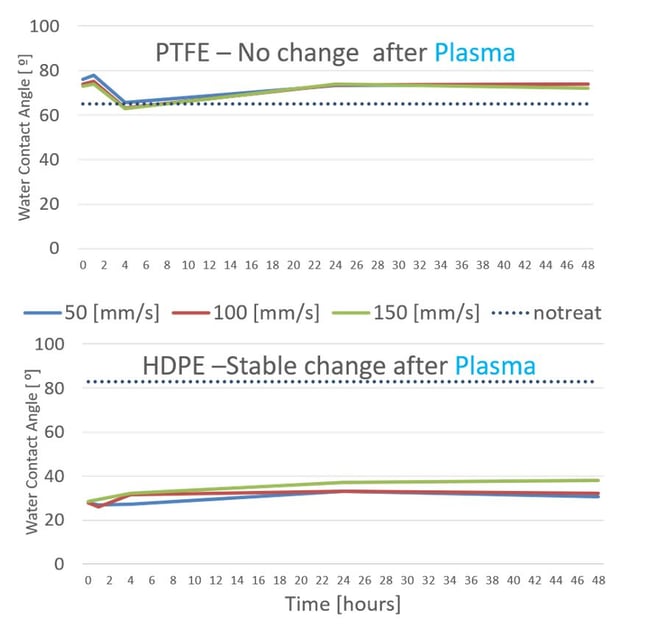

Figure 1 displays how different polymers (PTFE and HDPE) receiving the same treatment reacted differently to the plasma treatment and remained active and ready for adhesion for different lengths of time. In these trials, water contact angle measurements were used to gauge the quality of the surface over time. Each colored line represents various distances where plasma treatment was administered. The dotted line represents the polymer before treatment. You can see how, over time and depending on the material, the effect of the treatment can wear off and lead to adhesion failure.

Figure 1

Another way that time comes into play with treatment and preparation is determining how long to treat or clean a surface. It is possible to overtreat a surface and actually damage the material with overexposure to plasma or over-abrading.

3. What is the Environment?

If all of these processes were being performed in a sterile vacuum, then time would scarcely be a factor. But like many things in life, this just isn't reality. The environment to which the material surface is exposed can be one of the most critical factors in determining how long surface treatments are effective before the surface degrades back to an unclean state.

There are two ways that environments affect adhesion - absorption and physical contact.

1. Absorption can look like a hot environment (due to ventilation and machinery creating heat), making thermoplastics deteriorate quickly and allowing those contaminants under the surface to bloom to the top.

Additionally, if cleaning and surface treatment is being done near machinery performing tasks such as molding, forming, or abrading, then chemical debris can contaminant the atmosphere of the area and ultimately contaminate the critical bond surface.

2. Physical contact not only refers to how the material is handled by employees but also the chamber where treatment and cleaning are happening. Soiled washing fluid that hasn’t been adequately changed will inevitably produce parts with contaminated surfaces. Similarly, contaminants within treatment chambers where plasma treatments are taking place can easily transfer to a material surface that is being "treated."

4. How Are Materials Handled, Stored, and Shipped?

The time it takes a material or part component to reach a manufacturing facility, the time it spends in storage, and the time it spends in whatever container it is held in all have tremendous effects on every process step thereafter. There are some unexpected ways that storage time can unknowingly alter a material's surface.

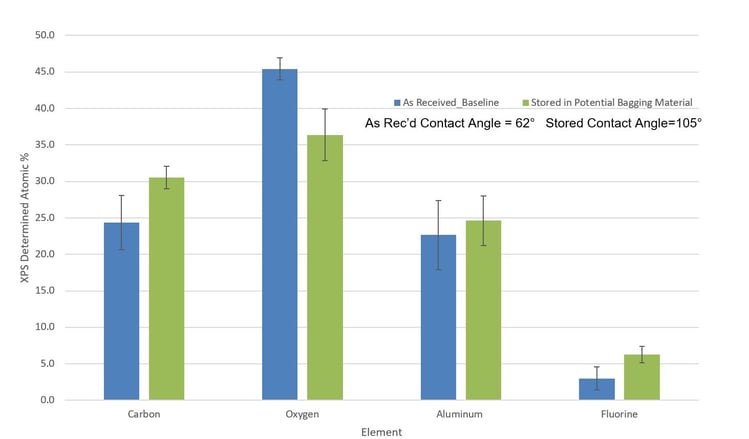

Figure 2 shows how various molecules changed on the surface after a part was stored in plastic wrapping. These changes occurred directly as a result of the transferring of elements from the plastic. Both carbon and fluorine impact adhesion, and the amount found on the surface increased significantly after exposure to plastic wrapping.

To ensure perfect adhesion, the surface must have a precise chemical makeup. As you can see, the contact angle changed dramatically (from a 62-degree angle to a 105-degree angle) after storage.

Figure 2

The impact of time is multifaceted and needs to be controlled on many levels. Not giving adequate thought to how time is a key player in the state of material surfaces means not controlling and managing every aspect of a product's lifecycle.

It is necessary to call upon Materials Science experts who can complete a holistic aging study to show exactly how time impacts material surfaces during your process.

Optimize the power of next-gen connectivity with data & surface intelligence.

Understanding the risk associated with these areas in the beginning stages of product development saves money, potential failure, and brand damage. Most importantly, it saves the sanity of everyone involved. Launch teams no longer need to hop on a flight across the globe to uncover the root cause of adhesion or coating failure.

Partnering with surface intelligence experts and implementing surface quality specifications enable development and manufacturing teams to successfully control their material surfaces throughout the entire product lifecycle and eliminate invisible contaminants that plague production.

Download the eBook The Advanced Guide to Transforming Product Development Through Surface Intelligence Data & Technology to learn how to utilize surface intelligence within your business.