Dyne solutions have been the most common method of quality-checking material surface cleanliness for decades. Their ubiquity and low cost have led them to be heavily relied upon by manufacturers even though they are imprecise, destructive to surfaces, and harmful to the user. The science behind dyne measurements is solid and trustworthy, but their use in manufacturing does little to help prevent or curb adhesion failure.

This article will explore the limitations of dyne testing and introduce you to the top alternative that will revolutionize your testing process.

What is Dyne Testing?

Dyne testing revolves around the notion of surface energy or wettability, which directly relates to how well a surface can adhere to substances. By observing how a substance interacts with a material or substrate, valuable insights about the material's surface energy can be gained. The reaction of the dyne solution will differ depending on the level of surface energy present.

A dyne is a unit of measurement used to measure force. A dyne per centimeter is the unit used to measure the surface tension of liquids. Surface tension is a suitable way to estimate the surface energy of a material, which is an excellent indicator of adhesion failure or success.

However, focusing on the kind of measurement dyne testing provides is indirect and approximate.

In the video below, Dr. Giles Dillingham, Founder & Chief Scientist of Brighton Science (formerly BTG Labs), describes how dyne testing is used in greater detail.

Within each of the points above lies an issue inherent to the use of dyne inks and pens. Looking closer at each one, it becomes very apparent that this method of surface cleanliness validation has some major drawbacks.

Not All Dyne Inks Are Created Equal

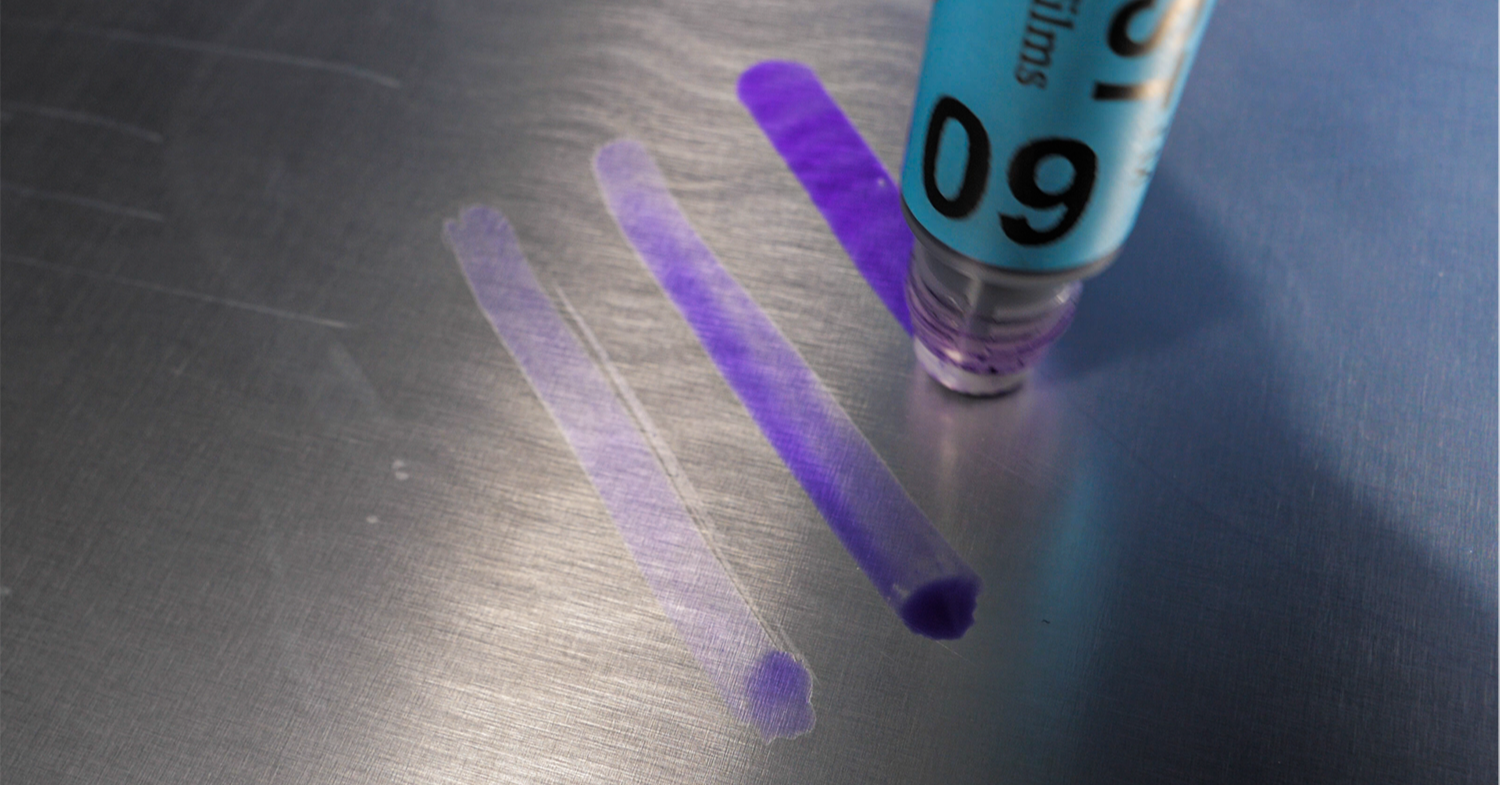

Dyne testing has proven to be unreliable due to various factors. Different brands of dyne test pen makers exhibit variations, making it impossible to equate one number or dyne level across different brands. This lack of consistency creates uncertainty regarding the accuracy and reliability of the pens. Furthermore, certain brands offer a wider range of numbers compared to others, potentially leading to a situation where numbers within the appropriate range for your surface might not be available.

Get hands-on with your surface cleanliness with the Surface Analyst 5001.

Dyne Solutions Are Destructive

As previously mentioned in the fundamental aspects of dyne solutions, it is important to note that these solutions are solely applicable to samples of parts and not the actual parts undergoing manufacturing processes. This is due to the caustic nature of the inks. They cannot be used on the production line due to their carcinogenic and teratogenic (harmfulness to a fetus in utero) characteristics.

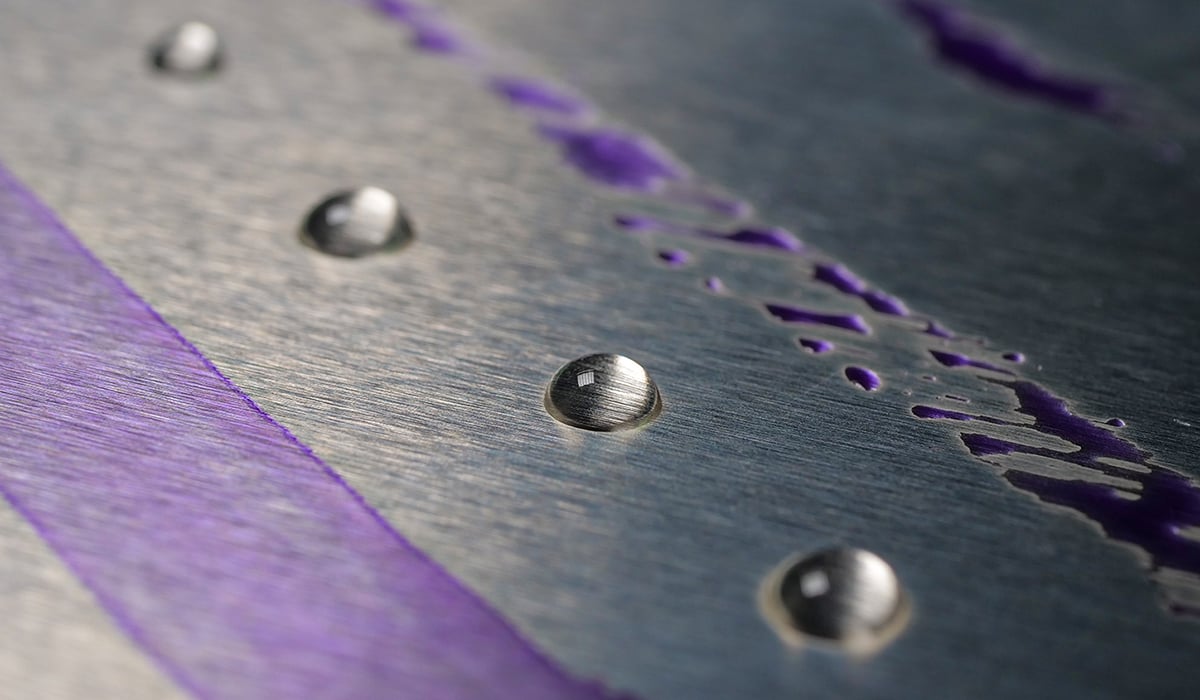

They are also destructive to the parts they are being applied to, so the materials that are actually being used in the adhesion process are not the materials being tested. Moreover, the initial purpose of dyne testing was to evaluate the surface quality of polymers exclusively. The packaging of dyne ink explicitly cautions against using it on metal due to its non-removable nature. However, despite this advisory, employing dyne ink on metal surfaces remains a widespread practice.

The dyne pens are also a threat because the tips of the pens can pick up contamination from one surface and transfer it to the surface being tested after. Consequently, these tests become futile as it is impossible to determine the contamination the inks indicate.

Here's another video of Giles explaining more of the science behind using dyne solutions and some drawbacks.

The Interpretation of Dyne Ink & Surface Wettability Results Remains Subjective

The concept of wettability is widely employed across various industries to qualitatively gauge the level of attraction between a fluid and a surface. A surface is considered wettable if it exhibits a low contact angle when in contact with a fluid, such as dyne solutions.

The way dyne ink behaves on a surface can be compared to a gradient, and when users examine its behavior, it's similar to perceiving a glass as half full or half empty. The ink's characteristics can only fall into two categories: bead up or wet out. If users have different interpretations of what qualifies as these characteristics, they might mistakenly identify something as positive or use a different pen unnecessarily.

A significant amount of training is required to properly read the activity of dyne ink on a substrate and make an informed decision about how to proceed. But even still, there is variation among trained users. This training also needs to include understanding about what the ink does to the surface of a material.

Adhesion occurs on the top 2-3 molecular layers of a surface. The dyne ink itself is a solvent and has a tendency to cut through these top few molecular layers – the most crucial element to adhesion. Therefore, the ink may be testing or reacting to layers that are below those layers that won’t actually be exposed in the adhesion application. This can lead to either false positives or just an inaccurate reading.

Dyne Ink Isn’t Enough

Extensive preliminary research is necessary to determine the appropriate dyne ink number for a surface. This entails formulating a testing procedure specification that aligns with the adhesion performance criteria of the final product. This just means that the adhesion needs to stick to the degree prescribed by the development team.

Surface quality measurements need to be done throughout the production process to validate the effectiveness of surface treatments such as plasma treatment or corona treatment. Having a surface quality check before and after these procedures ensures higher control over the surface quality. Being able to correlate those specs into a dyne test means either a lot of costly and imprecise trial and error or even more damaged test samples. These options aren't typically feasible for most manufacturers; therefore, using a dyne level as the standard can reinforce unsupported logic. The “when this number pen wets out, we are good to go” logic lacks any nuance and is a flimsy foundation for material surface quality control.

In this next video, Giles offers insight into why it is very hard to get reliable and trustworthy data from the use of dyne solutions.

Why Dyne Testing? There is Another Way

Essentially, dyne test solutions are a go/no-go method that gives no indication of what precise changes need to be made if that part failed the test or any indication of why it may have succeeded. These methods are disguised as quantitative tests because they associate a number with the surface, but they offer little to no actionable data that can be relied on. Trends cannot be mapped, and the results are dubious at best.

A truly repeatable, quantitative surface energy measurement needs to be done directly on material surfaces being bonded, coated, glued, sealed, printed on, or painted. This inspection test needs to be fast, easy, accurate, and (very importantly) non-destructive. Contact angle is a true quantitative process control method that has all of the implied benefits of a dyne solution without any of the drawbacks. Contact angle measurements accurately measure surface energy and assess surface cleanliness and quality directly on real parts and components without sacrificing time, samples, or anyone's health.

Enhance the accuracy and effectiveness of testing material surfaces with our comprehensive eBook. Gain in-depth knowledge and discover a superior alternative to dyne testing. Download the eBook "What is Dyne Testing? Enhance Precision & Effectiveness with the Ultimate Alternative to Dyne Testing."