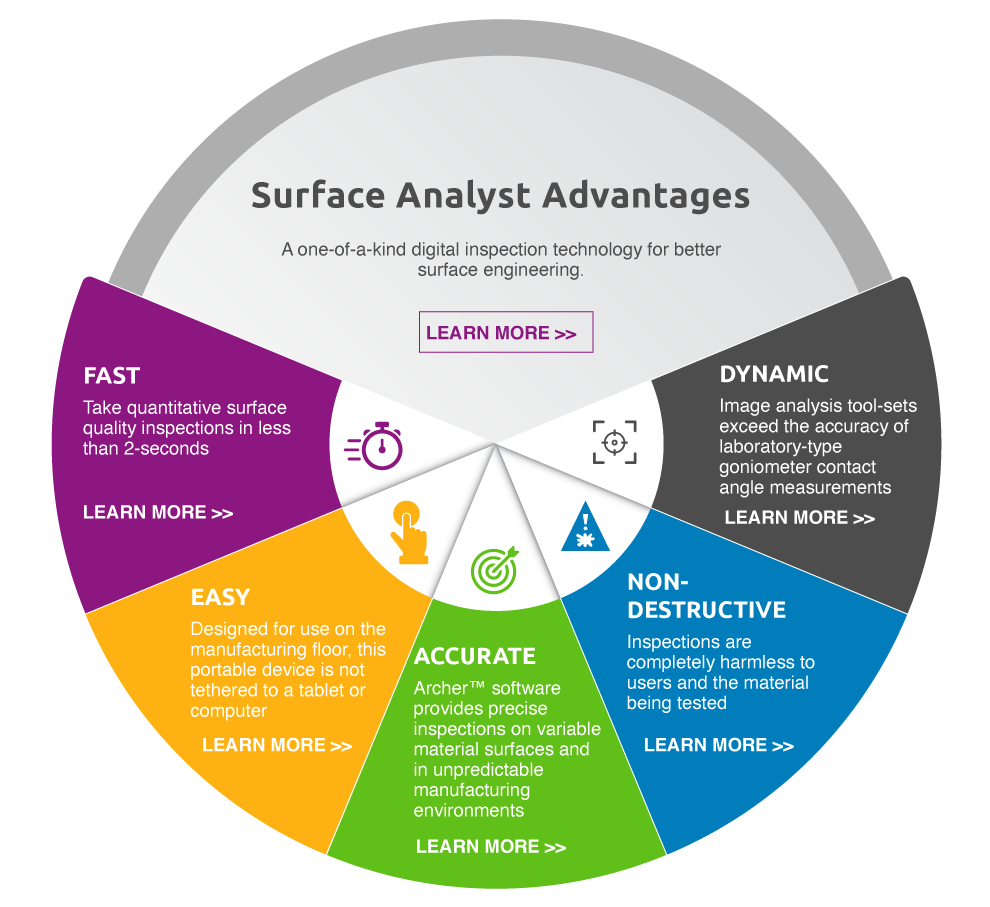

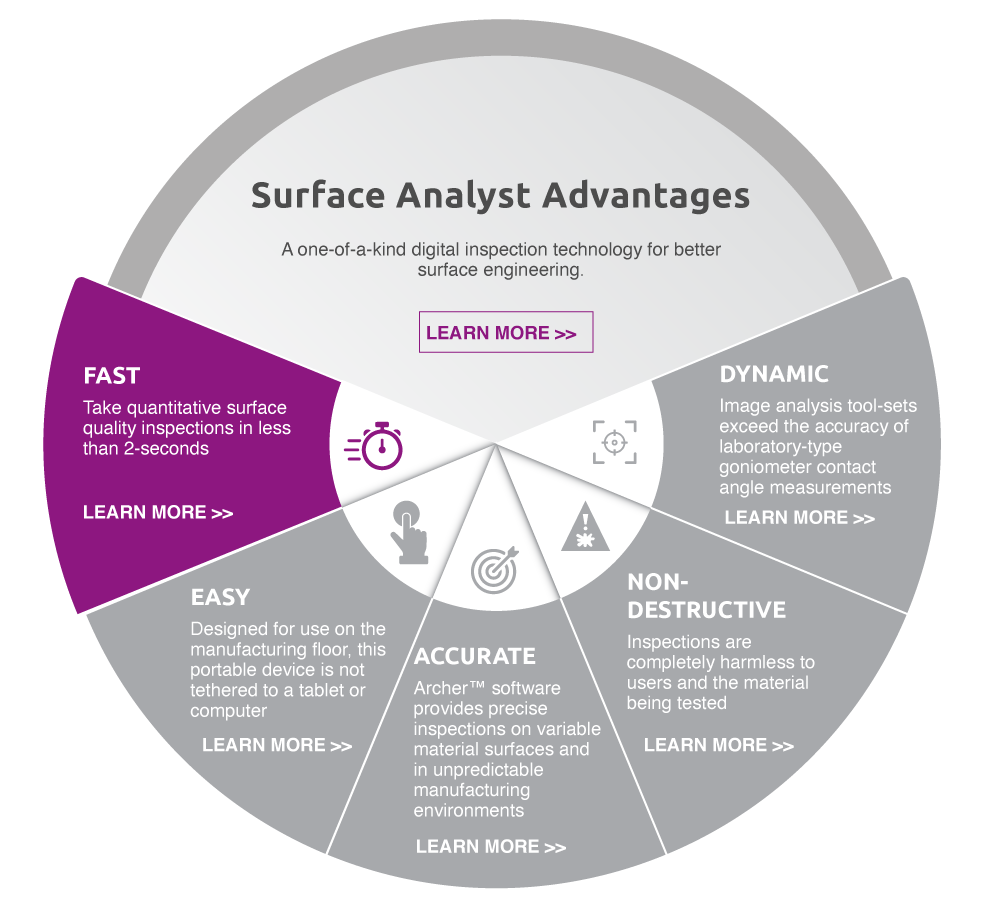

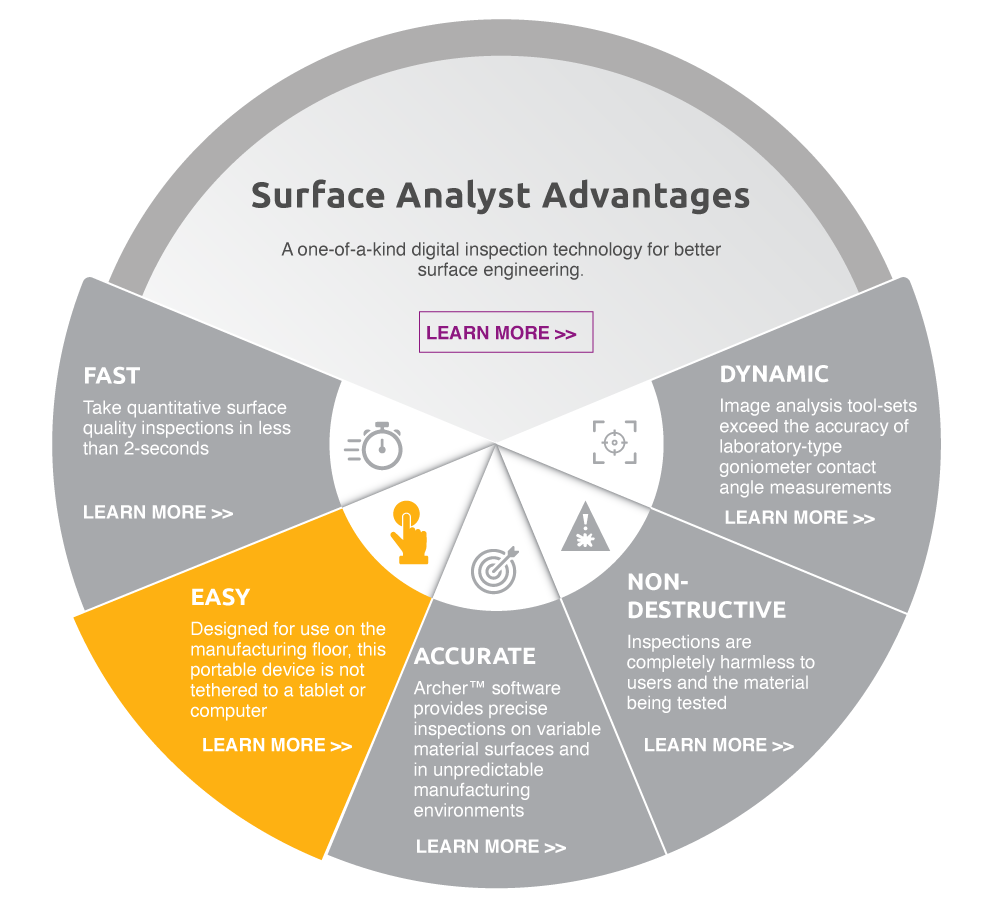

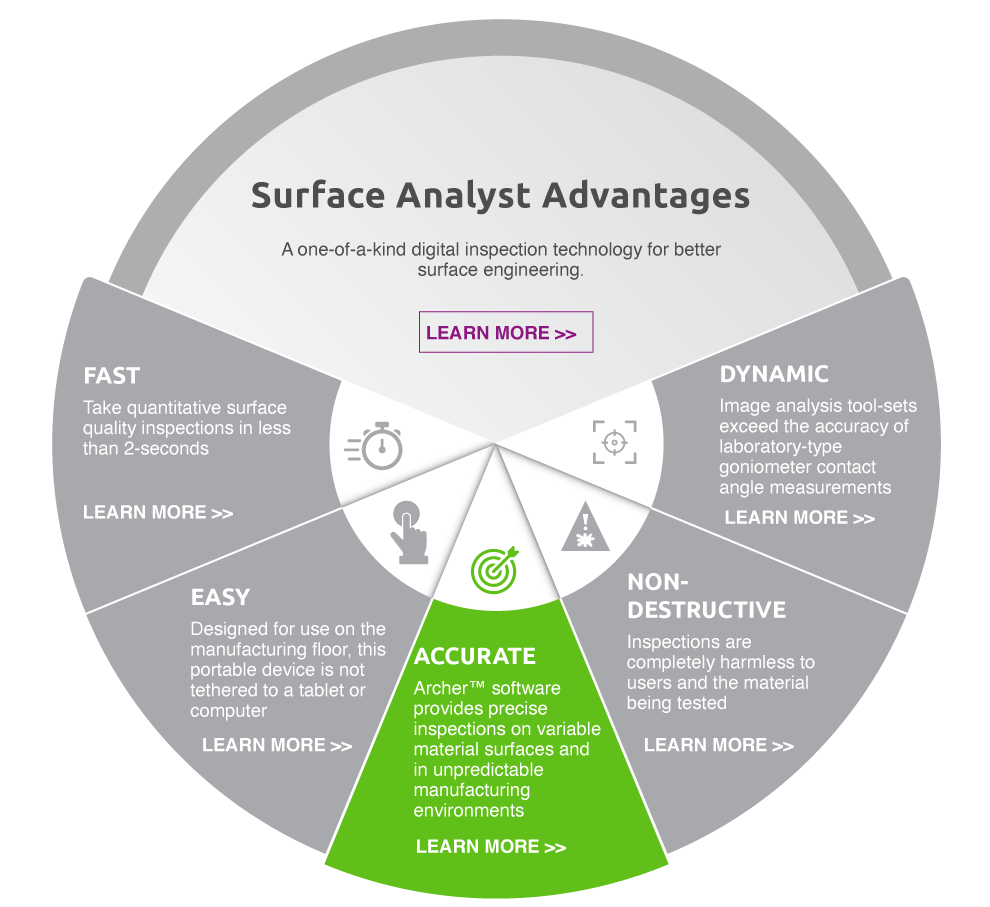

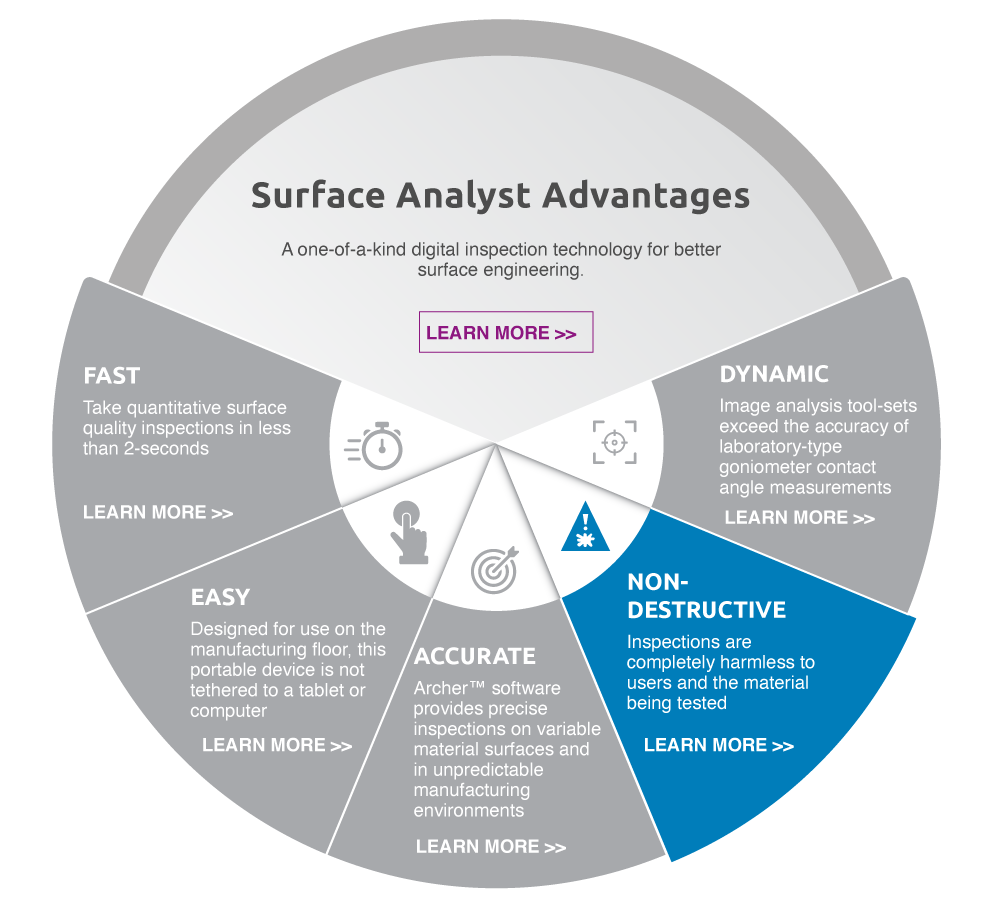

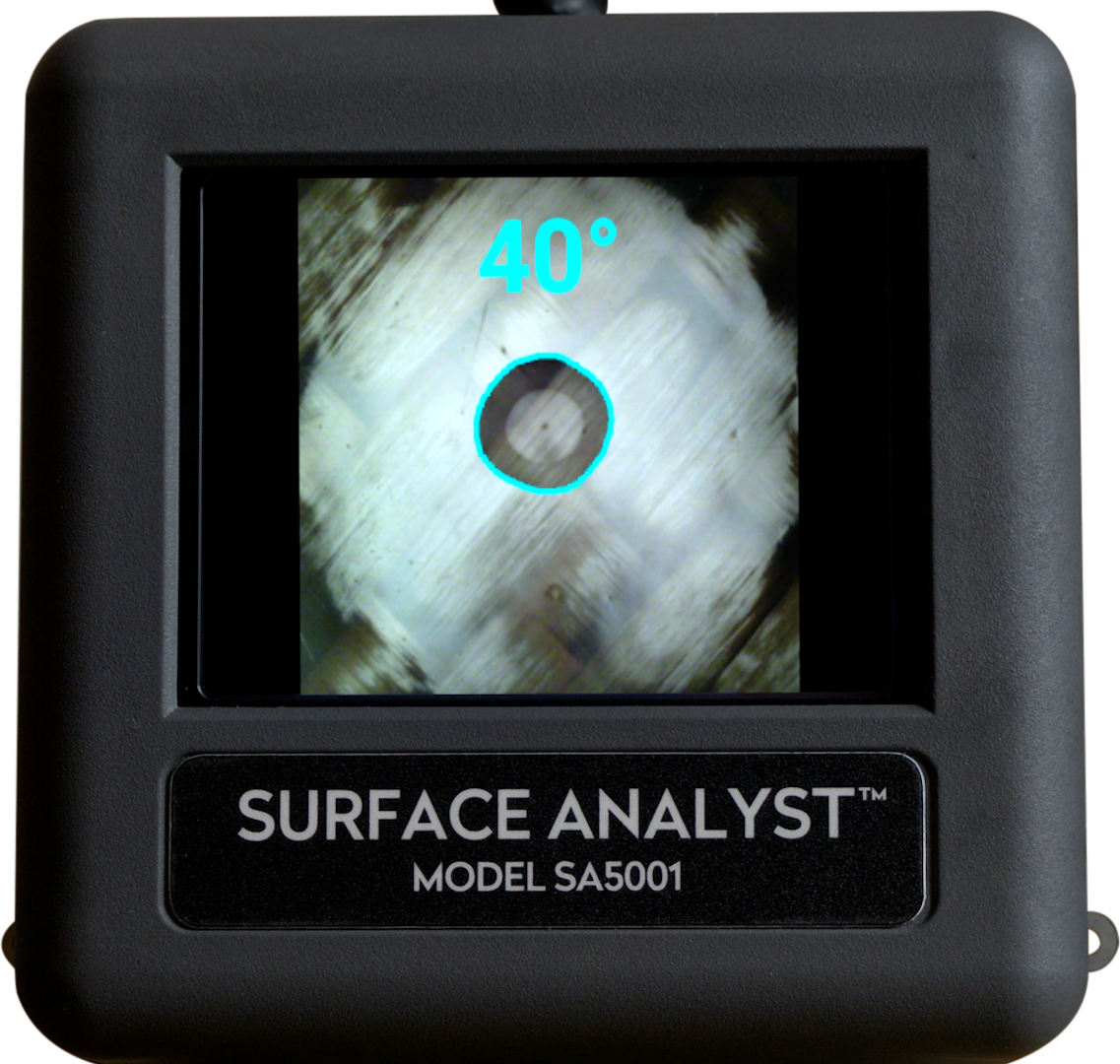

One of the most important features of the Handheld Surface Analyst is its innovative use of top-down imaging of the deposited drop, rather than the side view used by laboratory-type goniometers.

Brighton Science's top-down approach allows contact angle measurements to be obtained on surfaces of real-world objects that have features or orientations that prevent side viewing of a drop. Examples of these types of surfaces include: a populated circuit board, a tiny catheter, a machined metal casting, or a rough composite material surface where the hills and valleys prevent seeing the drop's edge with a side view.

When a drop of fluid is deposited on a real-world surface, it rarely produces a perfectly round droplet due to texture or chemical heterogeneity of the surface. This means there will be a range of contact angles around the drop perimeter. A side-view measurement only measures 2 of those angles and can give an erroneous picture of the true surface state.

The Surface Analyst with Dynamic Detection uses a patented top-down imaging approach to measure up to 200 points around the entire drop.

This innovative measurement provides a contact angle that more accurately represents the droplet's interaction with the surface and provides precise information about the true state of the surface.