This paper reviews research progress in the detection of contamination on surfaces for bonded composites.

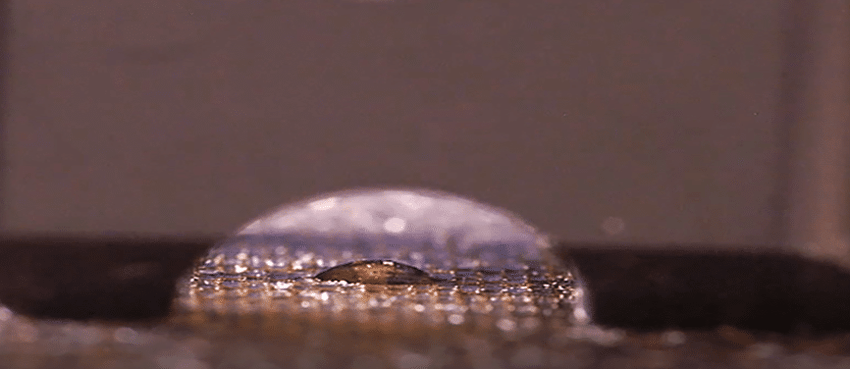

Results to date indicate that it is possible to use a simple handheld instrument to determine if a composite surface is in such a state that a durable bond can be achieved.

Results to date indicate that it is possible to use a simple handheld instrument to determine if a composite surface is in such a state that a durable bond can be achieved.

This study examined both airborne and contact contamination and found that contact contaminants can originate from unexpected sources. Monitoring of airborne contaminants in various manufacturing locations indicated that discrete contamination events could occur that are potentially detrimental to adhesion.

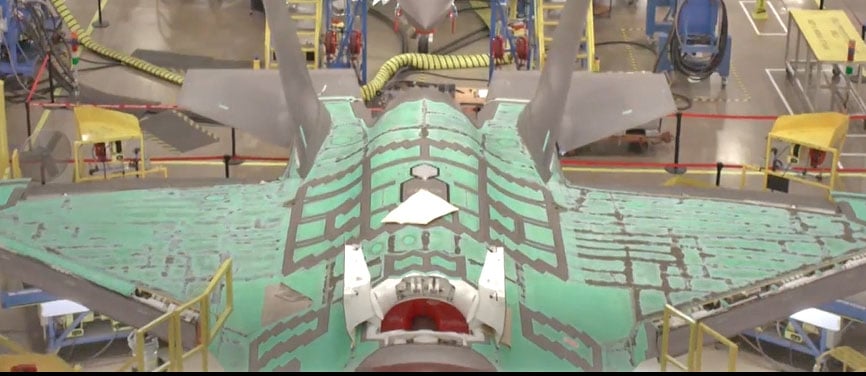

Improving Composite Bonds in Aircraft

The Surface Analyst™ technology has many of its roots in the CAI (Composites Affordability Initiative) program from the mid to late 1990s. This industry/government partnership comprised a team charged with addressing the perceived risks and barriers to the more widespread use of composite materials in aircraft design. The collaboration included members from the Air Force Materials Laboratory, the Office of Naval Research, Bell Helicopter Textron, The Boeing Company, Lockheed Martin Corporation, and Northrop Grumman Corporation.

Evaluating Bonded Composites for Reliability

As part of our role, we worked with Boeing and AFRL to evaluate surface energy measurements as predictors of the bondability of composite surfaces. One of our partners at AFRL, Robert Crane, is a respected expert in techniques for the non-destructive evaluation of composites. Applied Composite Materials has published this paper.