Insights

No matching resources. Please try a different filter

eBook

eBook

eBook

eBook

eBook

eBook

Article

Article

Article

Article

Article

Article

Webinar

Article

Webinar

Article

Webinar

Article

Article

Article

Article

Article

Article

Webinar

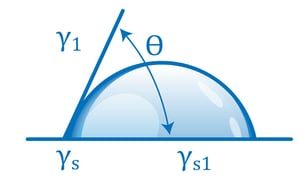

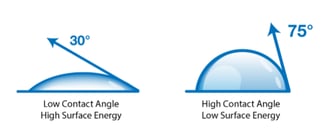

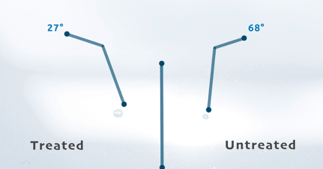

Webinar: Shifting from Dyne Solutions to Contact Angle Measurements

47:22 min to watch

Article

Article

Case Study

Article

Video

Article

Technical Paper

Article

Article

Article

Technical Paper

Article

Article

Webinar

Article

Article

Article

Article

Technical Paper

Article

Article

Article

Article

Webinar

Article

Article

Article

Article

Article

Article

Article

Article

Article

Webinar

Webinar: Top 3 Strategies to Improve Your Adhesive Bonding Operations

60.00 min to watch

Article

Article

Article

Webinar

Article

Video

Webinar: Creating a Digital Thread for Surface Preparation of Composites

60.00 min to watch

Article

Article

Article

Article

Article

Article

Webinar

Webinar

Article

Webinar

Article

Webinar

Article

Case Study

Webinar

Article

Article

Article

Article

Technical Paper

Webinar

Webinar

Webinar

Article

Video

Webinar

Webinar

Webinar

Webinar

Webinar

Webinar

Article

Technical Paper

Article

Webinar

Technical Paper

Technical Paper

Technical Paper

Webinar

Technical Paper

Webinar

Case Study

Technical Paper

Case Study

Case Study

Case Study

Webinar

Webinar

Technical Paper

Technical Paper

Technical Paper

Technical Paper

Technical Paper

Article

Article

Article

Article

Article

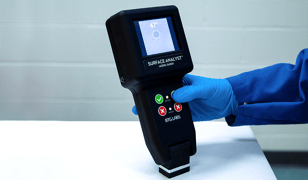

Brighton Science is

the global leader

in surface intelligence.

Tell us your goals or challenges, and we can advise you on specific solutions you can put to work immediately or build into your optimization processes.

What could this mean for you?